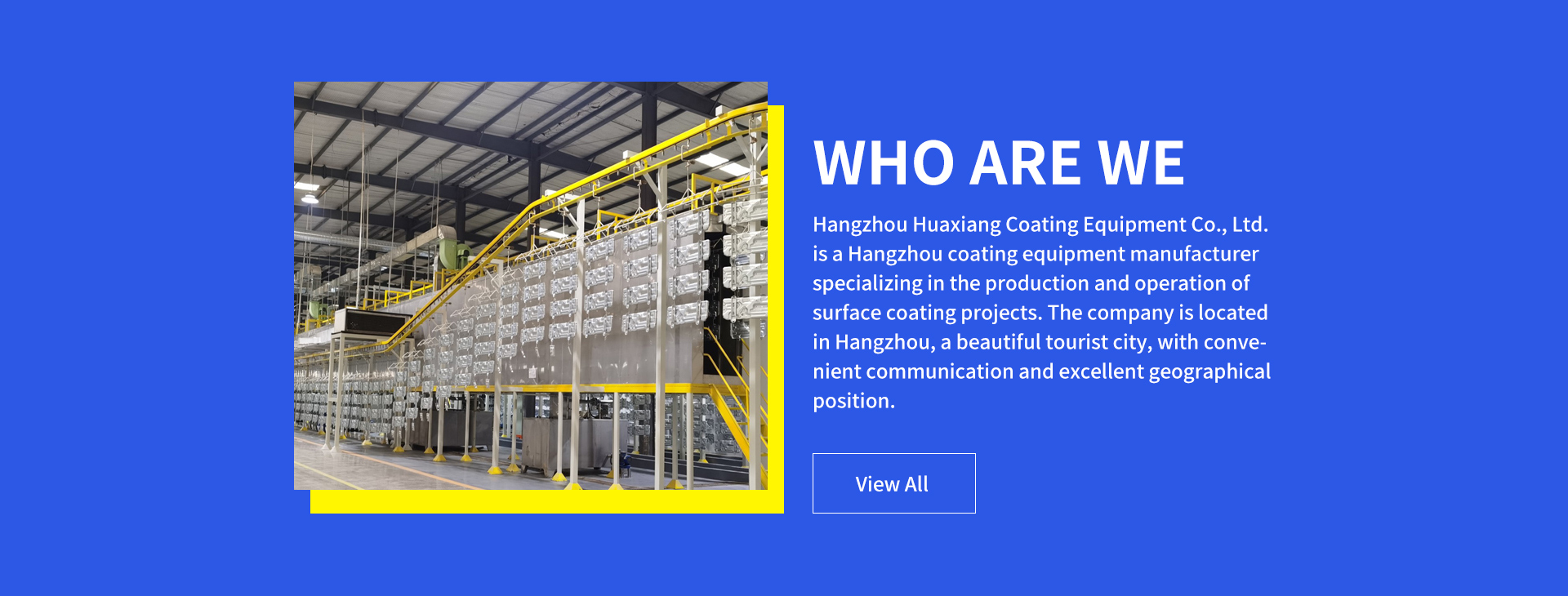

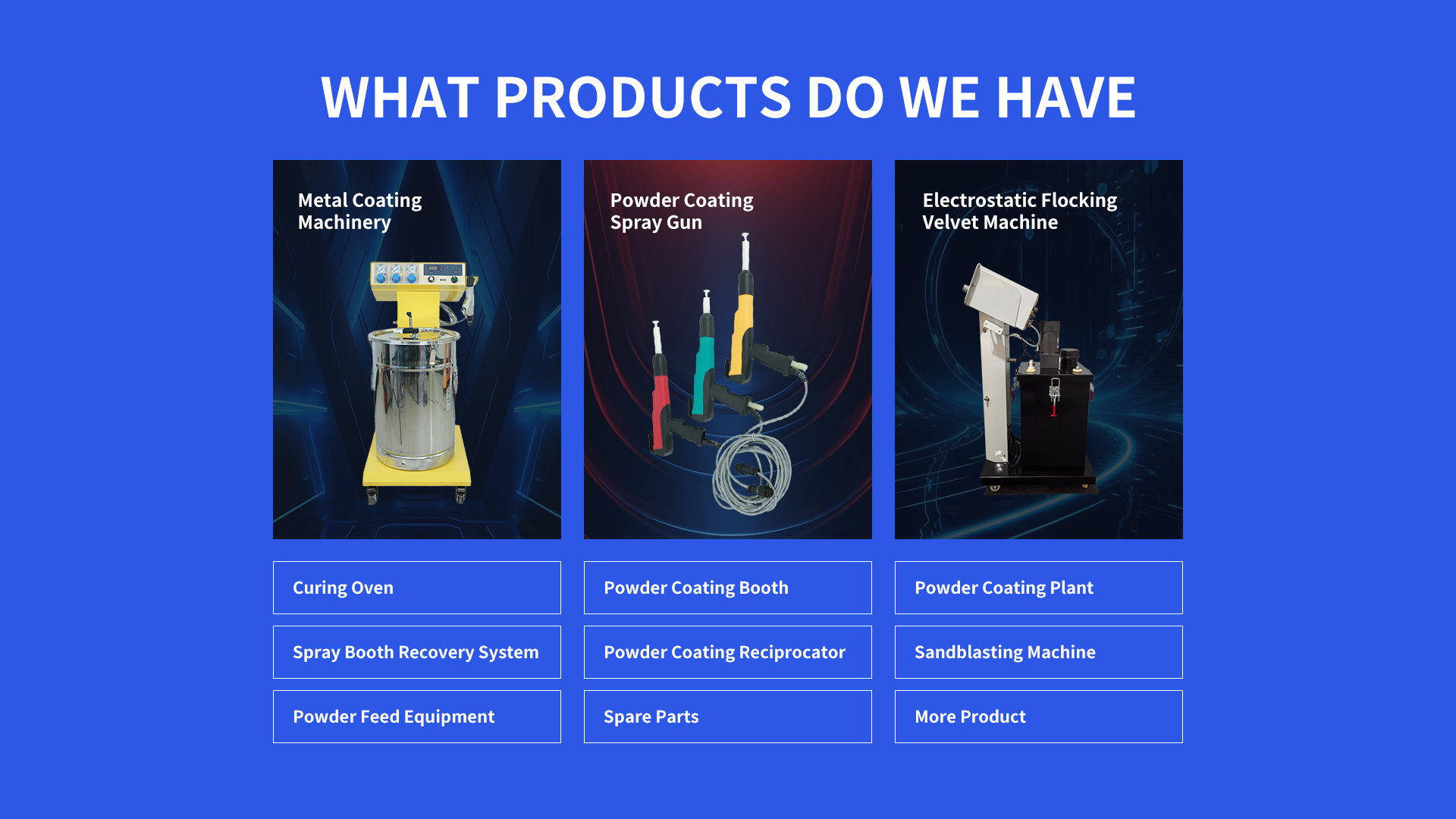

In the dynamic realm of powder coating, the Industrial Powder Coating Booth serves as an indispensable asset, acting as the cornerstone for achieving seamless and top - notch coating operations.

Introduction and Structure

An

Industrial Powder Coating Booth is a meticulously engineered enclosure designed to optimize the powder coating process. At its core, a high - performance ventilation system is integrated. This system is tasked with expelling over - sprayed powder particles, thereby maintaining a pristine and hazard - free working environment.

Powder - reclaim systems, such as efficient cyclones or precision cartridge filters, are an integral part of the booth. These systems are adept at capturing and recycling the excess powder, not only reducing material waste but also cutting down on production costs.

Illumination within the booth is equally crucial. High - quality lighting fixtures are installed to ensure bright and even illumination. This enables operators to execute spraying tasks with utmost precision, resulting in a consistent and professional finish.

The interior walls of the booth are carefully designed to be smooth. This smooth surface not only facilitates easy cleaning but also aids in the efficient collection of powder, further enhancing the overall functionality of the booth.

Application Scenarios

In the automotive manufacturing sector, these booths are the go - to solution for coating car bodies and various components. They ensure that every curve and surface of the vehicle receives a uniform and durable powder coating, enhancing both the aesthetic appeal and the longevity of the cars.

Metal furniture factories heavily rely on industrial powder coating booths to coat large - scale metal frames. The booths enable the application of a thick and even layer of powder, protecting the furniture from corrosion and wear while adding a touch of elegance.

For the production of industrial machinery components, these booths play a vital role. They guarantee that the components are coated with a high - quality finish, capable of withstanding harsh operating conditions and maintaining their performance over time.

Equipment Prices

For small - scale industrial operations, basic booths are a cost - effective option. Priced in the range of 10000, these booths come equipped with essential features like a basic ventilation system and a simple powder - reclaim mechanism.

Mid - range booths, with their enhanced powder - reclaim systems and improved ventilation capabilities, are priced between 20000. They offer better performance and durability, making them suitable for medium - sized production facilities.

High - end industrial - grade booths, equipped with state - of - the - art features such as automated powder - reclaim systems and high - efficiency ventilation, can cost upwards of $20000. These booths are engineered for large - scale production lines, delivering maximum productivity and top - tier coating quality.

Correct Usage

Prior to commencing any powder coating operations, it is imperative to conduct a thorough check of the ventilation system. Ensure that all ducts are clear, and the fans are operating at optimal capacity. Similarly, the powder - reclaim system should be properly set up, with all filters and collectors in place.

Adjust the lighting fixtures to provide the right amount of illumination based on the nature of the spraying task. During the spraying process, keep the booth's doors tightly closed to prevent any powder leakage. This not only ensures a clean working area but also maximizes the efficiency of the powder - reclaim system.

After use, perform a comprehensive cleaning of the booth. Remove any powder residue from the walls, floors, and equipment. This regular maintenance routine helps to prolong the lifespan of the booth and ensures consistent performance.

Selection Tips

Production volume is a key factor to consider. For high - volume production, a booth with a high - capacity powder - reclaim system is essential. This will ensure that the excess powder is efficiently collected and recycled, keeping the production process running smoothly.

The types of workpieces also matter. Large - sized workpieces may require a larger booth with sufficient space for easy maneuverability. Additionally, consider the complexity of the workpiece shapes. Booths with adjustable interior fixtures can be more accommodating for irregularly shaped items.

Setting a budget that aligns with your long - term production plans is crucial. While it may be tempting to opt for a cheaper option initially, investing in a higher - quality booth can save costs in the long run through reduced maintenance and improved productivity.

Safety Precautions

Personal protective equipment is non - negotiable. Wear a high - quality dust mask to prevent the inhalation of powder particles, safety goggles to protect your eyes from any potential splashes, and gloves to safeguard your hands.

Proper ventilation is the cornerstone of a safe working environment. Ensure that the ventilation system is functioning correctly at all times. This will prevent the accumulation of powder in the air, reducing the risk of fire and explosion hazards.

Powder is combustible, so it is essential to keep all flammable materials well away from the booth. This includes solvents, oils, and other combustible substances.

Rationality Analysis

The powder - reclaim system is a game - changer in terms of cost - savings. By recycling the excess powder, businesses can significantly reduce their material expenses over time.

Good ventilation is not only crucial for safety but also for the quality of the coating. A well - ventilated booth ensures that the powder is evenly distributed, resulting in a more consistent and durable finish.

The overall design of the booth, with its smooth interior walls and efficient layout, allows for easy maintenance and efficient powder coating. This not only saves time but also enhances the overall productivity of the coating process.

Q&A

Q: What if there's too much powder in the air during spraying?

A: Immediately stop the spraying process. Thoroughly inspect the ventilation system for any blockages, such as clogged ducts or malfunctioning fans. If the airflow is insufficient, adjust the fan speed or clean the filters to improve the ventilation efficiency.

Q: Can I modify the booth for different powder types?

A: Modifications are possible, but they must be carried out with caution. Any changes should not compromise the booth's overall functionality. Before switching powder types, clean the booth thoroughly to prevent cross - contamination. This includes cleaning the powder - reclaim system, the interior walls, and all equipment within the booth.

Q: How often should I clean the powder - reclaim system?

A: The frequency of cleaning depends on the powder usage volume. In general, it is advisable to clean the powder - reclaim system every few uses. Regular cleaning helps to maintain its efficiency, ensuring that the excess powder is effectively collected and recycled.

Q: What if the booth's lighting is not enough?

A: First, check the bulbs for any signs of burnout or damage. If the bulbs are in good condition, inspect the wiring for any loose connections or faults. If necessary, upgrade to more powerful lighting fixtures to ensure proper visibility during the spraying process.

Q: Can I expand the booth's size?

A: Expansion may be feasible, but it is essential to consult the manufacturer first. The manufacturer can provide guidance on the compatibility of expansion options and ensure that the structural integrity and functionality of the booth are not compromised.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com